Check valve is two-port valve, meaning it has two openings in the body, one for fluid to enter and the other for fluid to leave. Check valve, also be called non-return valve or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. There are various types of check valves used in a wide variety of applications. In household RO water purify system, check valve is a small but important component.

The role of check valve in RO water purifier:

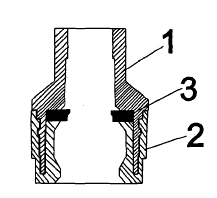

Check valve, also known as non-return valve, back pressure valve, one-way valve. This kind of valve is automatically opened and closed by the force generated by the flow of pipeline mediation itself, it is a kind of automatic valve. Used in household RO water purifiers, between RO membrane outlet and pure water pressure barrel (water tank), it is RO membrane pure water fitting. The pure water produced by RO membrane can flow only from RO membrane to water tank, and can’t flow back, the water purifier stops working when water tank is full. The check valve is located in the pure water outlet of RO membrane vessel, is the first component that pure water contacts after being produced, its role is to prevent backflow of the pure water from leading to waste of resources.

Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. An important concept in check valves is the cracking pressure which is the minimum upstream pressure at which the valve will operate.

To resolve the issues of low upstream pressure at some areas, WISNEX invented and developed the models of LARGE FLOW check valve, with the patent for invention No.2013100385724, 2013200559539. We can manufacture this kind of LARGE FLOW straight check valve, elbow check valve. Through our extensive testing, It has good performance even at low water pressure situation.

Feed water pressure and outflow comparison table:

| Water Flow | |||

| Feed water pressure | WISNEX Large Flow Check Valve | General Type Check Valve | Result |

| 0.05 Mpa (7.25 PSI) | 1.8 L/min | 0.3 L/min | 6:1 |

| 0.25 Mpa (36 PSI) | 2 L/min | 0.8 L/min | 2.5:1 |

Features Of WISNEX LARGE FLOW Check Valve

- Low cracking pressure requirement (high sensitivity)

- Large water flow

- Not easy to block

- Good abrasion resistance

- Good sealing

- Long working life